Roll‚ÄëDown Hurricane Shutters: How They Work, How Long They Last, and How to Maintain Them

Roll‑down hurricane shutters are engineered protection systems that unfurl from a roller head and travel in vertical tracks to cover windows and doors, forming a continuous barrier against wind, rain and flying debris. In this guide we explain how these shutters operate, the factors that determine their service life, and the everyday maintenance and installation choices homeowners can use to keep them reliable. Coastal properties face specific risks—salt corrosion, motor wear and improper installation—that shorten service life, so you’ll find clear inspection checklists, cleaning steps, and simple rules for deciding when to repair or replace. We also compare manual and motorized options, summarize energy and insurance benefits, and show how to estimate costs and request a free quote. The sections that follow cover product basics, expected lifespan ranges, maintenance cycles and seasonal checklists, when to call a pro, installation best practices, the value shutters add to a home, and how to use the online cost calculator to get a tailored estimate.

What Is a Roll Down Hurricane Shutter and How Does It Work?

A roll‑down hurricane shutter is a retractable curtain made of interlocking slats that wind into a headbox and run down guide rails to secure openings against storms. The system uses a roller assembly, slats, guide rails, endlocks and either a manual crank or an electric motor to deploy and lock the curtain into place, creating an impact‑resistant surface. Properly installed, the assembly protects glass by absorbing and deflecting debris and transferring wind loads into the structure—an important part of meeting code and keeping occupants safe. Knowing the main components and how they interact helps you prioritize maintenance and spot problems early; the next sections cover common materials and how motorization choices affect longevity and upkeep.

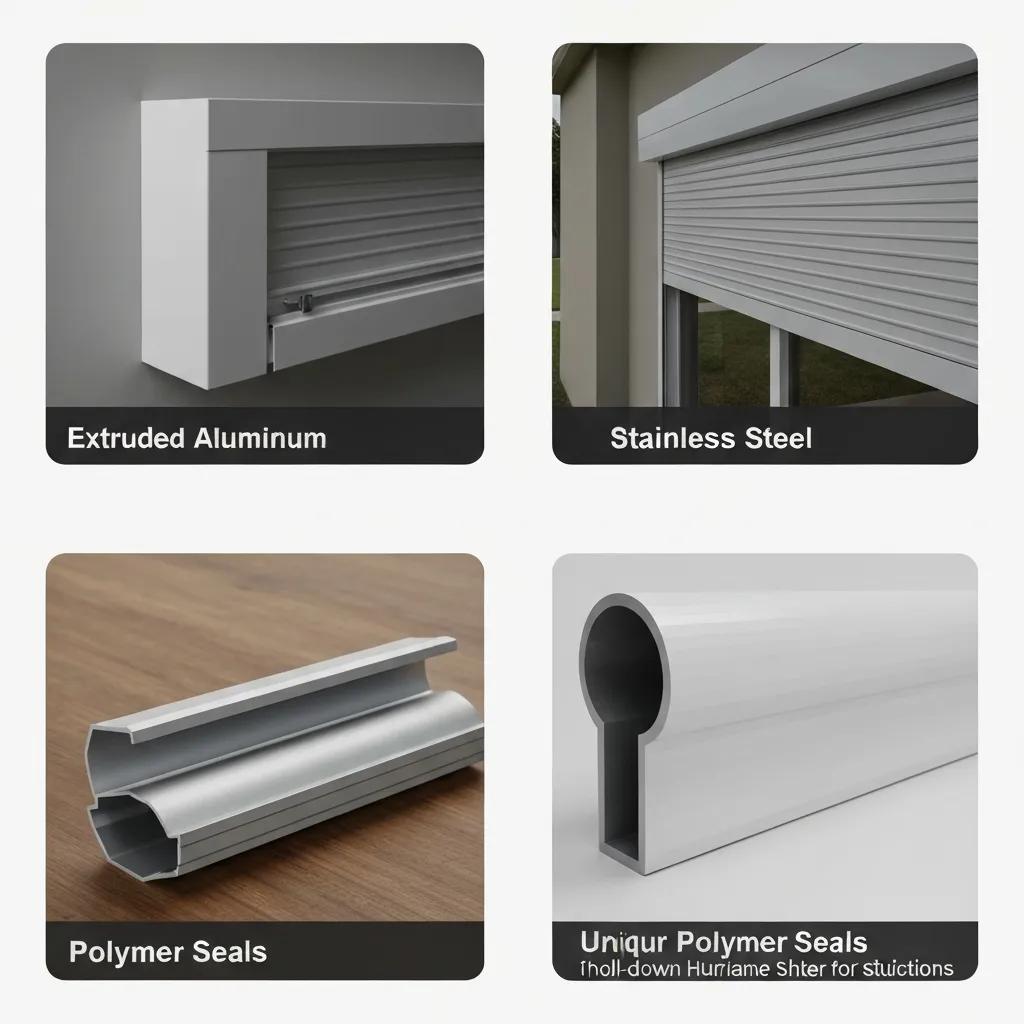

What Materials Are Used in Roll Down Hurricane Shutters?

Most roll‑down shutters use extruded aluminum slats for the curtain, stainless or other corrosion‑resistant fasteners for the hardware, and polymer weather seals to keep out water and reduce noise. Aluminum is lightweight and won’t rust; pairing it with 18‑8 stainless steel fasteners and brackets greatly improves coastal durability by resisting pitting and galvanic corrosion in salt air. Powder‑coat finishes add color and an extra corrosion barrier, but coastal exposures still require regular inspection. Choosing marine‑grade hardware and robust finishes directly reduces long‑term corrosion risk and improves the expected service life discussed later.

How Do Manual and Motorized Roll Down Shutters Differ?

Manual shutters use a hand crank or spring‑assist and are mechanically simple—often easier and less costly to repair—while motorized shutters use an electric motor and controls for fast, hands‑free deployment. Motorized systems add service points such as gearboxes, limit switches and remote controls, so they need scheduled electrical checks and occasional motor servicing. They do, however, shine where frequent operation or automation is important. Battery or generator backups are common to ensure operation during outages; typical troubleshooting focuses on power supply, motor brushes or limit‑switch settings. Choosing between manual and motorized models is a trade‑off between convenience and slightly higher servicing needs.

What Is the Typical Lifespan of Roll Down Hurricane Shutters?

With the right materials, installation and maintenance, roll‑down shutters typically last 15–25 years—and many systems last longer. Actual lifespan depends on material quality, corrosion resistance of hardware, how often the shutter is used, environmental exposure (coastal salt air speeds corrosion), and whether routine maintenance is followed. Correct installation that prevents misalignment and uses proper fasteners reduces mechanical wear; regular cleaning and lubrication stop abrasive salt and grit from seizing tracks and moving parts. The next paragraphs explain the main lifespan drivers and the warning signs that indicate repair or replacement is the better long‑term choice.

Material and hardware choices noticeably affect service life and corrosion resistance in coastal conditions.

Combining aluminum slats with 18‚Äë8 stainless hardware gives the best durability for coastal homes, extending functional life and reducing the need for mid‚Äëlife replacements.

Which Factors Affect the Lifespan of Roll Down Shutters?

Exposure to salt‑laden air and high humidity accelerates corrosion of unprotected hardware and degrades seals and finishes. Choice of materials—aluminum slats with 18‑8 stainless hardware, for example—directly improves corrosion resistance, while good coatings and proper drainage stop trapped moisture. How often you operate shutters also matters: frequent use without lubrication increases wear on bearings, rollers and tracks; poor alignment from improper installation causes slat binding and accelerates fatigue. Knowing these drivers helps homeowners prioritize actions like upgrading hardware, increasing maintenance frequency, or arranging professional inspections.

What Are the Signs That Indicate Roll Down Shutters Need Replacement?

Replace the system rather than repeatedly repairing it when you see structural damage (multiple deep dents, bent guide rails, or a deformed headbox that prevents deployment). Persistent operational problems after maintenance—jerky or seized movement, repeated motor burnout, or heavy corrosion at mounting points—mean mechanical integrity is compromised and replacement is the better investment. Worn or torn seals, ongoing water intrusion around frames, and loose or missing fasteners that can’t be safely corrected are other red flags indicating a full system upgrade will restore protection and help meet code requirements for storm events.

How Should You Maintain Roll Down Hurricane Shutters for Maximum Longevity?

Routine maintenance prevents corrosion and mechanical wear and keeps shutters ready when a storm approaches. A practical program includes monthly operational tests, quarterly cleaning for coastal sites, semi‚Äëannual lubrication of tracks and moving parts, and an annual professional inspection to check fasteners, motor performance and anchoring. Regular maintenance lowers the chance of emergency repairs and helps preserve warranty coverage; the following subsections give specific cleaning steps, lubrication guidance and seasonal checks, plus clear guidance on when to call a pro.

Here’s a simple cleaning sequence homeowners can do safely.

- Prepare the system: Turn off power to motorized units and secure manual controls before you start.

- Rinse loose salt and debris: Use a gentle fresh‚Äëwater spray to wash salt deposits from slats and tracks.

- Wash with mild soap: Apply a diluted gentle detergent and scrub slats and guides with a soft brush.

- Clean tracks and drainage: Brush out grit from tracks and flush with water to clear drainage paths.

- Dry and inspect: Wipe dry, check seals and fasteners, and note any corrosion or wear that needs attention.

Following these steps keeps abrasive salt from accumulating, preserves finishes and gets shutters ready for lubrication.

What Are the Step-by-Step Cleaning Procedures for Roll Down Shutters?

Always confirm power is off for motorized systems and that shutters are lowered or locked before cleaning. Rinse the curtain and guides with fresh water to remove salt and loose debris, then clean slats with a mild soap solution and a soft brush—don’t scrub hard enough to damage the finish. Pay special attention to the tracks and roller‑box throat where salt and grit collect; avoid high‑pressure washers that can push water into bearings or motor housings. Finish by drying exposed metal, checking weatherstripping, and listing any fasteners or seals that need tightening or replacement. That leads naturally into lubrication work.

Use these lubrication guidelines for shutter components.

- Use a silicone‚Äëbased lubricant: Apply on tracks and guide rails to reduce friction without attracting dust.

- Lubricate semi‚Äëannually: Twice a year is typical; increase frequency for severe coastal exposure.

- Avoid oil‚Äëbased sprays in tracks: Oils attract dirt and can cause abrasive wear over time.

- Apply sparingly: A light, even coat prevents buildup and keeps the curtain moving smoothly.

These rules reduce component wear and prevent buildup that leads to binding; adjust frequency based on your environment.

How Often and How Should You Lubricate Roll Down Shutters?

Plan on lubricating at least twice a year for most homes; coastal properties exposed to salt spray should consider quarterly lubrication. Choose a silicone‚Äëbased, water‚Äëresistant lubricant and apply a thin layer to guide rails, roller bearings and exposed pivot points, then cycle the shutter to distribute it evenly. Avoid petroleum‚Äëbased products in tracks since they collect grit; wipe away excess to prevent buildup. Regular lubrication smooths operation and reduces stress on motors and manual gearworks, making inspections more predictable.

What Does a Seasonal Inspection Checklist for Roll Down Shutters Include?

Inspect before and after storm season to catch issues early. Your checklist should include visual checks for corrosion on fasteners and brackets, testing motor or manual operation, and verifying seal integrity around openings. Tighten loose fasteners, test limit switches and remotes on motorized systems, and inspect the headbox for trapped debris or water pooling that can cause corrosion. Ensure weatherstripping is intact and drainage under guides is clear to stop water from entering the building envelope. Keeping a written checklist supports warranty claims and helps you decide when to call a professional.

When Should You Seek Professional Maintenance Services?

Call a professional when you face motor failure, significant corrosion on structural fasteners, damage to the headbox, or electrical issues beyond routine cleaning and lubrication. Pros safely service motors, replace marine‚Äëgrade hardware, calibrate limit switches and provide documentation that supports code compliance and warranty coverage. Expect a professional to run diagnostics, recommend targeted repairs and, when necessary, propose replacements to restore full protective performance. Escalating to trained technicians prevents risky DIY fixes and extends system life. In some cases professionals can also upgrade components to improve corrosion resistance and reliability.

What Are the Best Practices for Installing and Operating Roll Down Hurricane Shutters?

Correct installation and safe operation are essential for shutters to work when they’re needed and to reach their expected lifespan. Best practices include a detailed site survey and measurements, choosing the right mounting hardware for the structure and exposure, and testing full deployment and retraction under load before the job is complete. Safe operation protocols call for monthly test cycles, clearing the area before deployment, and clear instructions for manual override if power is lost. The following subsections explain why pro installation is recommended, list the key installation steps and outline safe operation procedures for both manual and motorized systems.

Key installation steps professionals follow are summarized below.

- Site survey and structural assessment: Verify framing and suitable anchoring points.

- Precise measurements and ordering: Measure openings and order correctly sized assemblies.

- Mounting and anchoring: Install headbox and guides with the correct fasteners and seal penetrations.

- Electrical wiring and motor setup: Install motors, set limit switches and provide backup power if required.

- Testing and documentation: Cycle shutters, confirm operation and train the homeowner on use and maintenance.

Following these steps reduces post‚Äëinstallation issues and helps homeowners operate their shutters correctly.

Why Is Professional Installation Recommended for Roll Down Shutters?

Professional installation ensures shutters are anchored to structural members that properly transfer wind loads into the building—avoiding failures that can occur with DIY attachment to non‑structural surfaces. Experienced installers perform Design Pressure Analysis to confirm assemblies meet required load ratings and code standards, and they select appropriate fasteners—often 18‑8 stainless steel in coastal areas—to resist corrosion. Professionals also calibrate motor limits and align curtains and guides to avoid premature wear. That technical accuracy reduces future repairs and often satisfies insurer verification requirements. Investing in pro installation protects both homeowners and the system’s long‑term performance.

What Are the Key Steps in the Roll Down Shutter Installation Process?

Installation begins with a thorough site assessment to confirm framing, measure openings and identify retrofit challenges such as trimmed sills or unusual reveals. The headbox and guides are positioned and fastened into structural backing with manufacturer‑specified anchors, then sealed and flashed to prevent water intrusion. For motorized units, wiring and controls follow—setting limit switches and programming remotes—then technicians cycle the shutter under load to verify smooth operation and make final adjustments. Finish with homeowner instruction on operation and maintenance, plus documentation for warranty and insurance purposes.

How Do You Safely Operate Manual and Motorized Roll Down Shutters?

Monthly test cycles keep operation predictable—always clear people and objects from the area before use. For manual systems use smooth, steady motion with the crank or spring assist and never force the shutter if you feel resistance. For motorized systems verify that remotes and wall controls work and know the backup manual override procedure if power is lost. Keep emergency operation instructions near controls and test any backup battery systems regularly. Regular testing and correct use reduce wear and ensure the system is ready when a storm approaches.

What Are the Benefits and Value of Investing in Roll Down Hurricane Shutters?

Roll‚Äëdown shutters provide primary storm protection by preventing glass breakage and reducing structural vulnerability, and they also deliver secondary benefits: improved home security, modest energy savings and reduced exterior noise. Closed shutters deter intrusion, reduce solar heat gain when used for shading, and improve acoustics because the curtain and seals add mass and an insulating air gap. Properly specified and professionally installed shutters may also qualify for insurance discounts when insurers recognize approved products and documentation. The table below summarizes typical benefits and their expected homeowner impact so you can weigh upfront cost against long‚Äëterm value.

The following table quantifies primary benefits and typical impact to a homeowner.

This comparison shows storm protection is the main value, while energy and noise benefits add comfort and potential cost savings over time.

How Do Roll Down Shutters Enhance Storm Protection and Home Security?

Roll‚Äëdown shutters form a continuous barrier of interlocking slats locked into guide rails and anchored to the structure. That barrier absorbs and deflects wind‚Äëborne debris, reducing the chance of glazing failure and subsequent water intrusion. The same physical resistance deters break‚Äëins by creating a visible, robust obstacle that is difficult to bypass. Shutters tested to required design pressures and installed with corrosion‚Äëresistant fasteners retain their protective performance over time, preserving structural integrity and occupant safety. These protective features also support potential insurance benefits when homeowners present approved product and installation documentation.

What Energy Efficiency and Noise Reduction Benefits Do Roll Down Shutters Provide?

Closed shutters reduce direct solar heat gain by shading windows and creating an insulating air gap that can lower HVAC demand in hot months—yielding modest energy savings depending on climate and how often you use them. The curtain’s mass and sealed edges also help reduce exterior noise, improving comfort in coastal neighborhoods or near busy roads. The degree of benefit depends on shutter fit, seal quality and usage patterns—homes that close shutters during peak sun or noisy periods will see the most consistent gains. These comfort and efficiency advantages make shutters useful year‑round, not only during storms.

How Can Roll Down Shutters Lead to Insurance Savings?

Insurers may lower premiums when a home has storm‚Äëmitigation features because shutters reduce the likelihood of costly wind and water damage claims. Typical requirements include approved product specifications and professional installation documentation. To pursue savings, retain manufacturer approvals, installation records and any Design Pressure Analysis or test certificates that show code compliance. Providing this documentation to your insurer supports eligibility for mitigation credits or premium reductions, making approved shutters and pro installation a financially sensible choice for many coastal homeowners.

How Can You Estimate the Cost and Get a Free Quote for Roll Down Hurricane Shutters?

Estimating cost begins with the main drivers: size and number of openings, motorized versus manual controls, material and finish choices, and installation complexity. Those inputs are applied to a per‑opening or per‑square‑foot calculation to produce a tailored quote. For a quick starting estimate, American Hurricane Shutters provides an online cost calculator and free consultation—enter window dimensions, shutter type and motorization preferences to get an initial estimate and instructions for the next steps. After using the calculator expect a follow‑up call or site assessment to finalize measurements and any structural upgrades so the final quote reflects real conditions.

Before the cost table, here’s a brief note on cost drivers and how estimates are calculated to guide homeowners.

Costs vary by project specifics; the online calculator turns these drivers into an actionable starting estimate and recommends a site visit for final pricing.

What Factors Influence the Cost of Roll Down Hurricane Shutters?

The biggest cost factors are total coverage area and the number of openings—larger or irregular openings require custom fabrication and heavier components. Motorized systems add the cost of motors, controls and wiring, plus possible backup power. Upgrades like stainless‑steel hardware and premium finishes increase materials cost but improve longevity. Installation complexity—retrofits into existing frames, masonry anchors or hard‑to‑access sites—drives labor and can materially affect the final price. Understanding these elements helps homeowners prioritize upgrades that deliver long‑term value, such as corrosion‑resistant hardware for coastal locations.

Use this process to get a more accurate starting estimate from the cost calculator and know what to expect after submission.

- Measure openings accurately: Enter width, height and opening type for each window or door.

- Select shutter options: Choose manual or motorized operation and any preferred finishes or upgrades.

- Note installation conditions: Describe retrofit challenges, access limits or unusual structural features.

- Submit and review: After the initial estimate expect a follow‚Äëup to schedule a site visit for final pricing and confirmation.

This process yields an immediate estimate and leads to a verified quote after an on‚Äësite assessment so pricing matches actual installation needs.

American Hurricane Shutters offers free consultations and an online cost calculator to convert your inputs into an immediate estimate and to schedule a follow‚Äëup site assessment. If you live in coastal North or South Carolina, requesting a free estimate is a practical next step to compare options and confirm that specified hardware and installation practices meet local exposure and code requirements.

Frequently Asked Questions

What are the advantages of using roll down hurricane shutters over other types of storm protection?

Roll‑down shutters offer several advantages over temporary options like plywood or fabric screens. They’re a permanent, durable solution that deploys quickly—often with motorized convenience—and they’re designed to withstand high winds and flying debris. Beyond storm protection, they improve home security and can deliver energy and noise benefits, making them a practical, long‑term investment for homeowners in storm‑prone areas.

Can roll down hurricane shutters be customized for different window sizes and shapes?

Yes. Manufacturers can customize roll‚Äëdown shutters for a wide range of openings, including arched or oversized windows. Custom units ensure proper fit, optimal protection and a clean appearance. Discuss your specific needs with a professional installer to confirm the right solution for your architecture.

How do I know if my roll down hurricane shutters are functioning properly?

Perform regular operational tests: the curtain should deploy and retract smoothly without unusual noises. Inspect tracks and slats for debris or corrosion and check that seals are intact. If you feel resistance during operation or shutters fail to lock securely, schedule maintenance or consult a professional for service.

What should I do if my roll down hurricane shutters get damaged during a storm?

When it’s safe, assess the damage and document it for insurance. Look for bent slats, damaged tracks or headbox deformation. If damage is minor and shutters still operate, perform maintenance; for significant structural or electrical damage, contact a professional for repair or replacement. Keep records and photos to support a