How to Install Accordion Hurricane Shutters: The Complete Step‚Äëby‚ÄëStep Guide

Accordion shutters are hinged, folding panels permanently mounted to protect windows and doors from high winds and flying debris. This guide walks homeowners and installers through planning, measuring, and installing accordion shutters the right way — because correct installation is what delivers the tested performance, code compliance, and safety those systems promise. You’ll get clear names for each component, exact measuring steps for daylight openings, a tools-and-materials checklist, phased installation instructions, and practical maintenance and troubleshooting advice to keep shutters working season after season. We also explain cost drivers, how to use an online estimator for budgeting, and where coastal North and South Carolina homeowners can request professional installation and a free estimate. Throughout, searchable guidance — how to install accordion shutters, accordion shutter installation tips, accordion shutter measuring guide — is woven into practical, field-tested best practices for DIYers and pro installers alike.

What Are Accordion Shutters and Why Choose Them for Hurricane Protection?

Accordion shutters are a permanently mounted folding system that deploys across an opening by unfolding panels that run in top and bottom tracks and lock in place. When properly anchored, they create a rigid, continuous face that resists wind pressure and blocks projectiles, helping prevent broken glass and secondary structural damage during storms. Typical materials include powder‑coated aluminum for corrosion resistance and stainless steel fasteners where anchoring strength and longevity matter — a combination well suited to coastal exposures. Accordion shutters offer rapid deployment, full‑coverage protection without storage needs, and a good balance of impact resistance and user-friendly operation for both homes and businesses. Understanding these parts and benefits helps you measure accurately, choose the right anchors and sealants, and install in a way that preserves the system’s engineered performance under Design Pressure guidance.

Coastal Homes: Shutter Systems for Hurricane Protection

Various shutter systems for windows and impact‚Äëresistant doors are designed to protect openings from wind and debris. These systems are tested and specified to resist the forces imposed by hurricane‚Äëforce winds and windborne debris.

Coastal Homes: Critical Design and Construction Issues, TP McAllister, 2002

How Accordion Shutters Protect Your Home

Accordion shutters protect openings by combining a continuous panel surface with anchored tracks that transfer wind loads into the surrounding framing. The system reduces concentrated load on any single fastener by spreading forces across multiple anchors and the shutter blades and tracks. In a coastal storm, correctly anchored accordion shutters stop large debris from striking glazing and lower inward wind pressures, which reduces the chance of window failure and subsequent structural problems. These shutters are often rated for specific pressure resistance, so following manufacturer instructions and local codes during installation is essential to achieve the protection those ratings represent. That’s why accurate measuring, correct anchor selection, and proper sealant application are priorities during every install.

Storm Shutters for Hurricane Protection: Design and Testing

This study reviews the structural design and testing of storm shutters used to protect windows and doors during hurricanes, including the development of a test facility and summary results.

Behavior of corrugated metal panels for use as storm shutters, 2009

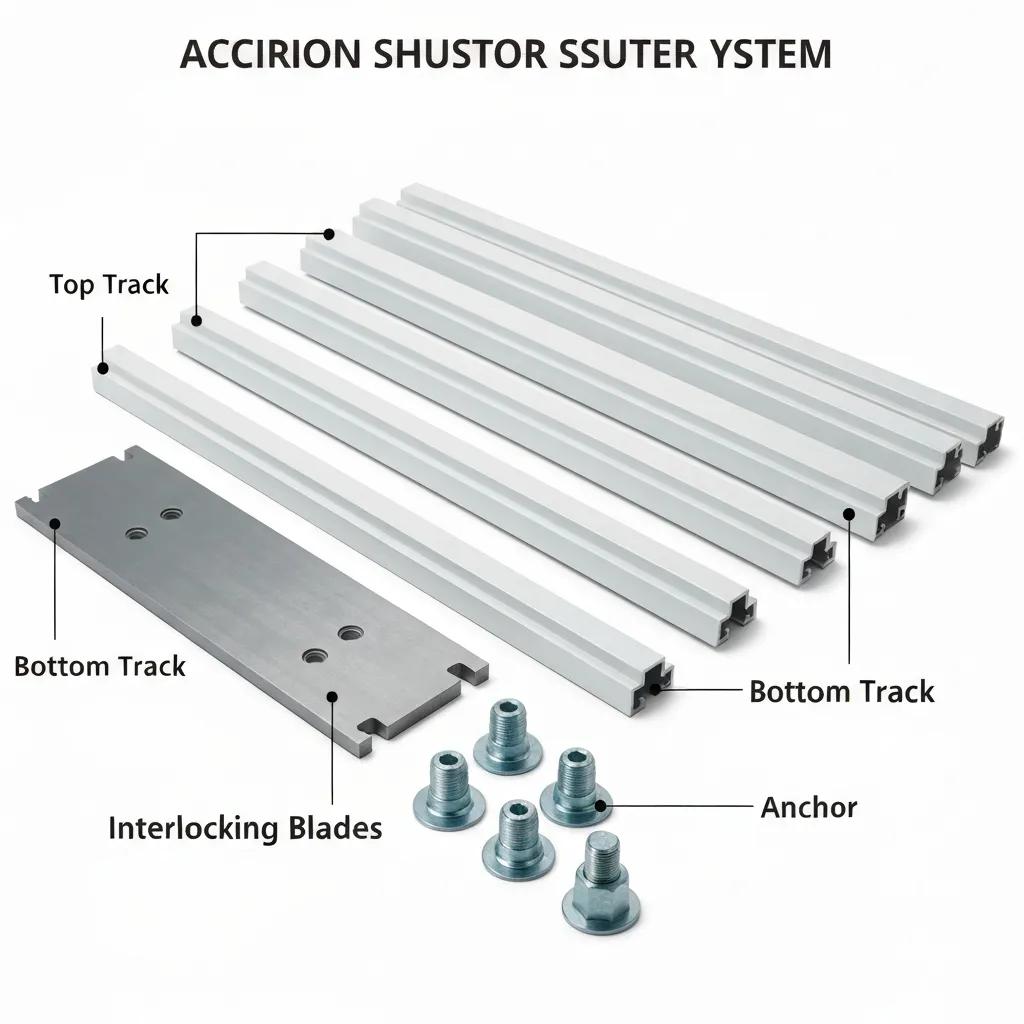

Key Components of an Accordion Shutter System

An accordion shutter assembly includes several parts that work together to create continuous protection: the top track, bottom track, interlocking blades, side angles, locking hardware, and anchors or fasteners into the structure. The top track guides blade movement and carries a share of wind loads; the bottom track stabilizes the panel and resists lateral movement. Blades interlock to form the impact face while side angles secure the edges to help prevent pry‚Äëout. Locks may be surface‚Äëmounted or embedded and must engage reliably under load. For coastal builds, corrosion‚Äëresistant anchors and stainless steel fasteners are commonly specified for durability. Knowing these component names helps you inspect, align, and install the parts that matter for smooth operation and rated performance.

How to Prepare for Accordion Shutter Installation

Preparation starts with precise measurements, the right tools and materials, and a decision on DIY versus hiring a pro. Good planning prevents common mistakes like ordering the wrong size, using incompatible fasteners, or misaligning tracks — issues that cause binding, leaks, or reduced performance. Confirm material specs (powder‑coated aluminum blades, corrosion‑resistant fasteners), review local building codes and any Design Pressure requirements, inventory all parts, and create a clear step sequence for mounting the top track, side angles, blades, bottom track, seals, and locks. That upfront work speeds installation and helps ensure long‑term, code‑compliant performance.

How to Measure Accurately for Accordion Shutters

Measuring requires three key numbers: daylight opening width and height, headroom (clearance above the opening for the top track and folded blades), and jamb‑to‑jamb distances. Measure width and height at three points (top, middle, bottom; left, center, right) and record the smallest dimension so the shutter won’t bind. Don’t measure to decorative trim — measure to structural jambs — and note out‑of‑square conditions so the installer can plan shims. Accurate measurements and recorded tolerances reduce the need for on‑site changes that can compromise anchors or seals.

Tools and Materials Needed for Installation

A concise tools-and-materials checklist keeps the job moving and helps match tool selection to the substrate and fastener type. The table below lists common tools, their use on the install, and recommended specifications to help you prepare.

This table explains how each tool or supply affects installation quality and why specification choices matter for long‚Äëterm performance. Having the right tools and materials on hand avoids delays and ensures proper anchors and sealants are used for coastal exposures.

Summary: The right tools and materials reduce rework, improve anchor integrity, and help meet Design Pressure expectations for coastal protection.

Should You Do It Yourself or Hire a Pro?

Choose DIY or professional installation based on opening complexity, wall substrate, local code requirements, and warranty needs. DIY is reasonable for small, square windows with simple framing; larger openings, sliding doors, multi‑story work, or masonry walls often require pro expertise. Professionals know anchor selection, large‑span alignment, correct fastener torque, and how to interpret Design Pressure guidance — critical for a reliable, warranty‑backed install in coastal North and South Carolina. If you prefer a pro, American Hurricane Shutters offers free consultations and estimates and can walk you through results from the Hurricane Shutter Cost Calculator — a sensible step for complex openings or warranty work.

Step‚Äëby‚ÄëStep Accordion Shutter Installation

Installations follow a clear sequence: prepare and organize components, install the top track with precision, fasten side angles and insert blades, set the bottom track and verify clearance, test operation and locks, then seal and inspect for gaps. Each phase transfers loads differently and requires specific checks — for example, a level top track prevents blade binding while correct anchor spacing and embedment prevent pull‑out. Use a step checklist to keep consistent quality control and verify every mounting action against the manufacturer’s instructions and local code. Below are focused subsections with common mistakes and troubleshooting tips for each critical phase.

Prepare the Opening and Organize Components

Start by clearing the opening, removing debris, and inspecting jambs and the head for rot, spalling, or irregularities that must be fixed before track mounting. Lay out parts in installation order — top track, blade packs, side angles, bottom track, fasteners, and locks — so everything is within reach and can be counted. Snap or pencil reference lines for center, level, and anchor spacing to speed drilling and ensure alignment, and pre‑drill pilot holes or countersinks where appropriate. This preparation prevents surprises and creates quality checkpoints before you commit anchors to the substrate.

Install the Top Track Correctly

Installing the top track begins with a level reference line; transfer anchor locations to the track and fasten it while keeping a continuous level across the opening to avoid blade binding. Place anchors at regular intervals into solid substrate so wind loads are transferred to framing; use corrosion‑resistant fasteners in coastal installations. After initial fastening, check level across the full length, make small adjustments as needed, and tighten anchors to the manufacturer’s recommended torque to avoid track distortion. Inspect straightness and plumb carefully before installing blades — mistakes here are the costliest to fix.

Summary: A precise top‚Äëtrack installation establishes the geometry for blade travel and overall shutter performance; get it right before moving on.

Attach Side Angles and Insert Blades

Fasten side angles after the top track is secure; align them plumb to your layout lines and anchor so blade ends engage properly during the full travel. Insert blades by angling the folded panels into the top track, then expand them and check for smooth travel from end to end. Listen and feel for binding — that usually signals misalignment or an out‑of‑square opening. Loosen nearby anchors, add shims, or adjust torque where needed to correct binding so blades interlock flush without excessive friction. Proper side‑angle alignment reduces wind‑driven rattle and prevents premature wear.

Secure the Bottom Track and Verify Clearance

Place the bottom track in line with the top track and side angles, confirming parallel alignment so blades keep uniform clearance through their travel. If the sill or threshold is uneven, use shims to maintain consistent clearance rather than forcing the track into an irregular surface, which can cause binding or seal failure. Anchor the bottom track into solid substrate where possible and ensure blade bottoms engage cleanly without catching on debris. Run multiple open/close cycles to confirm blades seat correctly and locks engage without excessive force.

Test Operation and Locking Mechanisms

Cycle the shutters fully several times to confirm blades slide freely and locks engage securely. Test locks under slight lateral pressure to verify engagement without jamming. Recheck alignment with a level after a few cycles and ensure hardware operates smoothly — stiff locks or intermittent engagement point to misalignment or loose anchors. If binding occurs, locate the binding point, loosen nearby anchors, re‑shim or reposition as needed, and retest until operation is smooth. Verify all lock hardware is accessible and that keyed or mechanical parts function reliably to deliver the intended security during storms.

Seal and Inspect for Gaps

Apply a continuous bead of compatible sealant with backer where required to prevent water and air infiltration while allowing for thermal movement. Seal between the side angle and jamb with a smooth finish for long‑term adhesion. Inspect all perimeters for gaps, paying close attention to top‑track transitions and sill interfaces — the highest risk areas for wind‑driven rain. Use a flashlight and inspect from both inside and out to find pinholes or unsealed spots, and touch up sealant where needed. A final checklist should include anchor torque, sealant continuity, lock function, and operational smoothness to ensure the installation meets weatherproofing and performance expectations.

Performance of Hurricane Shutters Under Impact

Building codes in hurricane‚Äëprone regions have evolved to require shutters for windows and doors to prevent damage from high winds and windborne debris. This study evaluated the impact performance of storm panels, including effects from concrete roof tiles.

Performance of hurricane shutters under impact by roof tiles, KR Gurley, 2010

How to Maintain and Troubleshoot Accordion Shutters

Regular maintenance keeps accordion shutters reliable and extends service life by preventing corrosion, wear, and mechanical failure. A basic maintenance routine includes periodic cleaning to remove salt and dirt, lubricating sliding surfaces to reduce friction, and cycling the shutters periodically to surface developing issues. Troubleshooting follows a simple symptom ‚Üí cause ‚Üí solution approach so homeowners can identify sticky blades, noisy operation, or lock problems and decide whether a DIY fix or professional service is needed. Performing routine checks preserves the engineered performance intended by Design Pressure recommendations and corrosion‚Äëresistant anchoring practices.

Essential Maintenance Tips for Accordion Shutters

Key maintenance tasks include rinsing powder‚Äëcoated aluminum with fresh water to remove salt, applying a silicone‚Äëbased lubricant to sliding surfaces, and exercising the shutters monthly to keep hardware moving and reveal early issues. Inspect visible anchors and fasteners for corrosion, especially near the coast, and replace compromised hardware with corrosion‚Äëresistant alternatives. Keep locks clean and lightly lubricated and test locking engagement during each seasonal check to ensure security during storm season. Maintain a simple log of inspections and interventions to support warranty or service claims.

Troubleshooting Common Accordion Shutter Problems

Use a quick troubleshooting approach to map symptoms to likely causes and fixes, and call a professional if the problem involves shims, anchors, or structural issues. Common problems include sticking blades from debris or misalignment — clean and lubricate the track, then check alignment; noisy operation from dry tracks or loose hardware — tighten fasteners and lubricate; lock failures from worn components or misaligned strikes — verify strike alignment and replace parts if needed. If anchors pull out, cracks appear in the substrate, or corrosion is extensive, engage a professional installer to restore rated performance.

How Much Does Accordion Shutter Installation Cost and What Affects Price?

Installation cost depends on several primary drivers: the number and size of openings, wall substrate (wood, masonry, stucco), anchor and hardware grade, labor and travel, and any permits or necessary upgrades to meet local codes and Design Pressure recommendations. Large openings like sliding doors use heavier components and more labor, raising costs relative to a single window. Coastal durability options — stainless‑steel anchors and custom powder‑coat finishes — add material cost but increase long‑term value. Travel, permit fees, and unexpected structural repairs discovered during prep also affect the final price. Understanding these variables helps homeowners use a cost estimator for a realistic budget and decide whether a free professional estimate is needed.

What Drives the Cost of Installing Accordion Shutters?

Smaller, straightforward windows usually require less material and time, yielding lower labor costs. Large patio doors or multi‚Äëstory installs increase material handling and alignment time, raising costs. Substrate matters: concrete or masonry takes longer to drill and needs specialized anchors compared with wood framing. Coastal specifications like stainless anchors and durable finishes increase material cost but improve longevity. Travel distance, permit needs, and any structural repairs found during preparation will also affect the final quote and should be considered early in the planning process.

Using a Cost Calculator to Estimate Expenses

A cost calculator lets homeowners enter variables — opening type and size, wall substrate, finish and anchor grade, and location — to generate a conceptual estimate that reflects material and labor drivers. Provide accurate measurements and substrate details for the best results. Treat the calculator as a budgeting tool, not a final quote; on‑site inspection is required to capture permit fees, access issues, and site conditions. For a precise, actionable quote, request a free consultation or estimate from a professional installer. American Hurricane Shutters offers a Hurricane Shutter Cost Calculator and free estimates to convert calculator results into a final installation plan.

Where to Get Professional Accordion Shutter Installation in Coastal NC and SC

Homeowners along the North and South Carolina coasts can find professional installers who focus on engineered hurricane protection, Design Pressure analysis, and corrosion‑resistant installation practices. Local providers understand regional codes and exposure patterns and can recommend appropriate anchors and finishes — such as powder‑coated aluminum and stainless‑steel fasteners — to ensure durability and compliance. Working with a local installer simplifies permitting and scheduling and ensures the installation reflects local storm loading rather than generic assumptions. For homeowners ready to move forward, a free consultation and estimate are the next practical step.

Why Choose American Hurricane Shutters in NC and SC?

American Hurricane Shutters follows engineered installation practices that reference Design Pressure analysis and corrosion‚Äëresistant hardware, including 18‚Äë8 stainless anchors for critical attachment points. We focus on powder‚Äëcoated aluminum materials and secure anchoring into structural framing to preserve rated performance in coastal conditions. Serving coastal North Carolina and South Carolina, our team knows local codes and common substrate conditions, which helps deliver a documented installation that aligns with regional storm exposure and compliance needs.

How to Request a Free Consultation or Estimate from American Hurricane Shutters

When you request a free consultation or estimate, have accurate measurements of your openings (daylight width and height), note wall substrate and any access challenges, and list preferences for finish or anchor grade. If you’ve already used a Hurricane Shutter Cost Calculator, share the results to help the estimator narrow the on‑site quote more quickly. American Hurricane Shutters provides free consultations and estimates to turn calculator outputs into final proposals that include local code, permit requirements, and site‑specific conditions. Scheduling a consultation is the recommended next step when you’re ready to move from planning to installation.

Frequently Asked Questions

What are the benefits of accordion shutters compared with other hurricane protection?

Accordion shutters are a permanent, on‚Äëframe solution that requires no storage and can be deployed quickly when a storm approaches. They give full coverage of openings, reducing the risk of wind and debris damage, and are typically made from durable, corrosion‚Äëresistant materials like powder‚Äëcoated aluminum. Their user‚Äëfriendly operation and clean appearance make them a favored choice for homeowners who want reliable protection with straightforward use and good curb appeal.

How can I tell if my home is suitable for accordion shutters?

Consider opening sizes and wall construction. Accordion shutters work well on standard windows and doors; larger openings may need professional assessment. Check local building codes for any specific requirements and confirm your walls have sound structural framing for anchor attachment. If you’re unsure, schedule a site visit with a qualified installer to confirm suitability and attachment details.

What maintenance do accordion shutters need?

Regular maintenance is simple but important: rinse off salt and debris, lubricate moving parts, and cycle the shutters periodically to keep hardware exercised. Inspect anchors and visible fasteners for corrosion and replace compromised parts with corrosion‑resistant hardware. Keep a short maintenance log to track inspections and work — it helps with warranties and long‑term performance.

Can accordion shutters be installed on any wall material?

They can be installed on wood, masonry, and stucco, but the attachment method and fastener choice will vary by substrate. Masonry often requires special anchors and drilling tools, while wood frame installations are typically quicker. Always select fasteners compatible with the wall type and follow manufacturer and code guidance; if in doubt, consult a professional installer.

What should I do if my shutters aren’t operating smoothly?

First, check the tracks for debris and clean them. Lubricate sliding surfaces with a silicone spray. If the issue persists, inspect alignment and ensure anchors and fasteners are tight. Misalignment or loose components often cause sticking. If you can’t resolve the problem safely, contact a professional for an on‑site inspection and repair.

Are warranties available for accordion shutters?

Yes — many manufacturers and installers offer warranties that vary in length and coverage. Warranties commonly cover material and workmanship defects; professional installation may include additional coverage. Read warranty terms carefully and keep your purchase and installation records to support any claims.